FAKRA wire beam streaming media wire harness Automotive parts wire harness

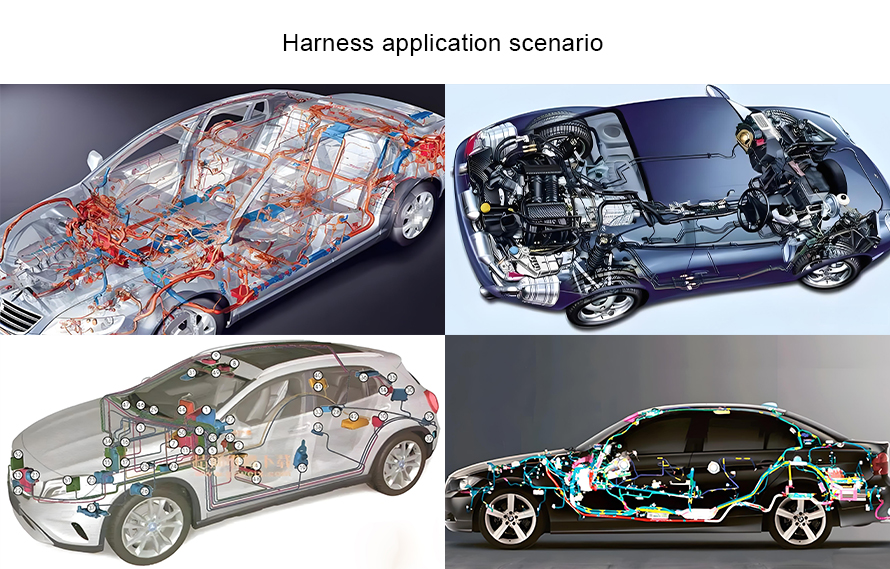

Auto parts wiring harness refers to the wiring harness between various electrical components inside the car. Wiring harness plays an important role in connecting and transmitting power, signals and data in the automobile, and is an indispensable part of the automobile electrical system.

The main function of the wiring harness of automotive parts is to connect the electrical equipment of various parts such as the instrument panel, engine, and body to form a complete electrical system. Wiring harnesses are usually made from a combination of multiple wires and are insulated and bundled according to the specific requirements of the car. The design and manufacture of wire harness need to take into account the electrical conductivity, durability, sealing, high temperature resistance, vibration resistance and other characteristics of the wire.

Harnesses can be divided into several main types: power harnesses, signal harnesses, and data harnesses. The power harness is mainly responsible for transmitting electricity and connecting the car's power system, including the battery, engine and electric motor. The signal harness is mainly responsible for transmitting various signals, including speed signals, turning signals, braking signals, etc. Data harness is mainly responsible for transmitting vehicle data, including vehicle diagnostic data, vehicle entertainment system data, etc.

The manufacturing process of automotive parts wiring harness includes three main links: wiring harness design, wiring harness processing and wiring harness detection. Wire harness design is based on the requirements of the car, determine the wiring of the wire harness, the length of the wire harness, the cross-sectional area of the wire harness and other parameters. Wiring harness processing is based on the design requirements, the insulation wire peeling, crimping terminals, inserting joints and other process operations, the various wires are combined into wiring harness. Wire harness testing is to test the wire harness through specific testing equipment after the processing is completed to ensure the quality and reliability of the wire harness.

The manufacturing of automotive parts wire harness mainly relies on professional wire harness manufacturing enterprises. These companies usually have advanced production equipment and technology, and can design and manufacture wiring harnesses according to the requirements of different models. Wiring harness manufacturers usually need to cooperate with automobile manufacturers, according to the requirements of automobile manufacturers to order production. Wiring harness manufacturers also need to strictly comply with the quality management system to ensure the quality and reliability of wiring harnesses.

With the continuous development of automotive technology, automotive parts wiring harnesses are also constantly innovating. The new wiring harness is made of more advanced materials with better temperature, vibration and oxidation resistance. At the same time, the new harness is also more compact and lightweight, helping to improve the performance and fuel economy of the car. In addition, with the rapid development of electric vehicles, new wiring harnesses also need to support higher currents and greater power transmission.

In short, automotive parts harness is an indispensable part of the automotive electrical system. The design and manufacture of wire harnesses takes into account a number of factors, including electrical performance, durability, tightness, and resistance to high temperature and vibration. With the continuous development of automotive technology, automotive parts wiring harnesses are also constantly innovating to adapt to new technologies and new needs. Wiring harness manufacturing enterprises in the car manufacturers to provide high-quality wiring harness at the same time, but also to continuously improve their own technology and management level to meet the needs of the market.