LVDS Wiring harness automotive wiring harness material

Antenna Advantage

Automotive wire harness material is an important component used in automotive electronic system, its role is to organize, protect and connect the wires of various parts of the car. The quality and performance of wire harness materials have an important impact on the safety and reliability of automobiles, so in the automobile manufacturing industry, the selection and use of wire harness materials are attached great importance.

First of all, automotive wiring harness materials need to have good insulation properties. Because the voltage and current in the automotive electronic system are relatively high, the wiring harness material must be able to effectively isolate the wire and the external environment to prevent short circuits or leakage between the wires. At the same time, the wiring harness material also needs to be able to resist the erosion of harsh environments such as high temperature, high pressure and chemical corrosion to ensure the safe operation of the wire.

Secondly, automotive wire harness materials need to have good wear resistance and pressure resistance. Due to the vibration and shock of the car, the wire harness material is vulnerable to the action of mechanical forces, so it is necessary to have a certain tensile strength and wear resistance to prevent the fracture and wear of the wire harness material during use. In addition, the wiring harness material also needs to be able to withstand the pressure of the car tire and the weight of the body to ensure the stability and reliability of the wiring harness.

In addition, automotive wire harness materials need to have good heat resistance. Due to the high temperature and long operation of automotive engines, wiring harness materials need to be able to withstand heat and smoke in high temperature environments, maintain stable performance and reliable service life. At the same time, the wire harness material also needs to have good cold resistance to adapt to the conditions of use in extremely cold environments.

In addition, automotive wiring harness materials also need to have a certain degree of flexibility and plasticity. Due to the complexity of the automobile body structure, the wiring harness material needs to be flexible and flexible to adapt to the installation requirements of different parts. At the same time, the wiring harness material also needs to have a certain degree of plasticity in order to facilitate the assembly and modification of the vehicle during the manufacturing process.

Automotive wire harness materials also need to have certain flame retardant properties. Because the car harness is in a closed space, once the short circuit of the harness or the overload of the wire occurs, a lot of heat and sparks will be generated, further triggering the fire of the vehicle. Therefore, wiring harness materials need to have flame retardant properties, can effectively inhibit the spread of flame, protect the safety of vehicles and passengers.

In summary, automotive wiring harness material is an essential and important part of automotive electronic system, and its performance is closely related to the safety and reliability of automobiles. With the continuous development and upgrading of automobile technology, the requirements for wire harness materials are becoming higher and higher. In the future, with the rise of new energy vehicles and intelligent vehicles, automotive wiring harness materials will face more challenges and opportunities, and need to continue to innovate and improve to meet the needs of the market.

Our advantages

|

|

|

Low cost Factories produce and sell themselves | Customizable About customization: Similar wiring harnesses can be customized - according to your drawings or sample requirements to customize the length of wiring harnesses, specifications, colors, etc., technology R&D one-to-one service Professional OEM and ODM Antenna Designer and Manufacturer | Specialized, refined, high Professional technology, precision equipment, high quality |

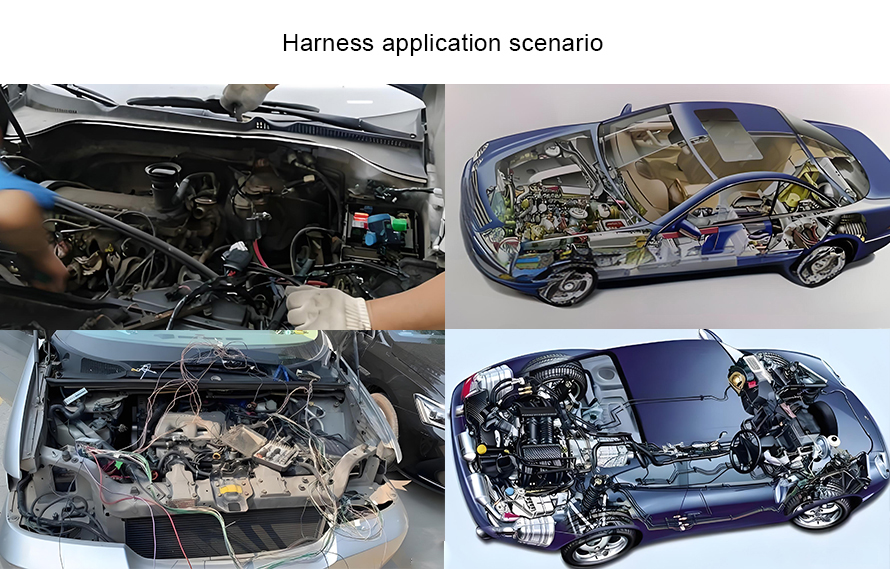

Applications